5 Reasons Why 3D Scanning is the Future of Orthopedic Measurements

Read time: 4 min

Accurate measurements are the base of every successful orthopedic treatment. Traditional methods like plaster casting or manual measuring often take a lot of time, create mistakes, and are not always comfortable for patients. 3D scanning gives a new way of working that combines accuracy, speed, comfort, and easy data storage. Many clinics now use a 3D foot scanner or foot scanner for insoles to achieve consistent, digital results.

Reason 1: Very Accurate

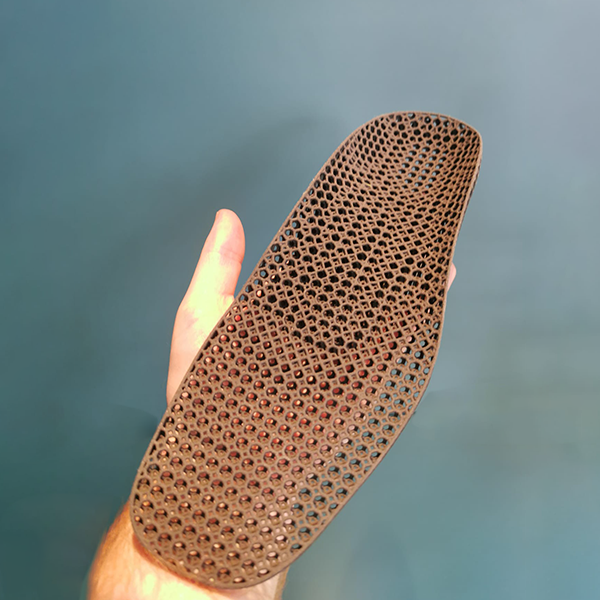

3D scanners reach a level of accuracy that old methods cannot. They record millions of points to make a full digital model of the foot, while manual tools only give a few numbers. This means even the smallest details of the foot shape are captured and can be used to design a device that fits perfectly. Using a dedicated foot scanner makes this process even more accurate because it is purpose-built for orthopedic and insole measurements.

Another big advantage is that human error is removed. With traditional measuring, results can change depending on how the tool is placed or how the numbers are written down. With a scanner, the results are always the same and can be trusted every time.

Scanners also capture the complete 3D shape, including curves and angles that cannot be measured by hand. This detailed picture helps create devices that not only fit better but also work better in daily use. A high-precision 3D foot scanner ensures these details are captured for better insole production.

Reason 2: Fast and Efficient

Modern 3D scanners can scan a foot in 5 seconds or less. Traditional casting often takes 15 to 30 minutes per patient. This means clinics save time, can help more patients, and reduce waiting times without lowering the quality of care.

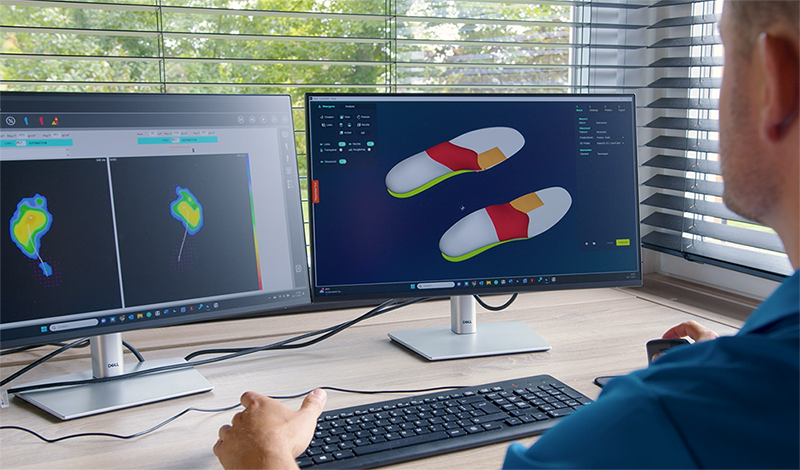

Because the scan is digital, the file can go straight into design software or directly to a production machine. There is no need to ship or store heavy plaster casts, and devices can often be made the same day or the next day.

If questions come up later about the fit or the design, the scan can always be checked again. There is no need to call the patient back for another measurement, which saves time and frustration for both patients and practitioners. For clinics producing custom orthotics, using a fast foot scanner for insoles makes the entire workflow even smoother.

Reason 3: Comfortable for Patients

Traditional casting can be messy, take a long time, and require patients to stay in uncomfortable positions. Scanning is completely different. It is clean, quick, and does not require much cooperation from the patient.

With modern scanners, patients can stand or sit in a natural position while the scan is taken. A handheld or platform-style 3D foot scanner is especially helpful for children, elderly patients, or people with limited movement.

Because the process is simple and stress free, patients feel more comfortable and positive. When patients have a good experience, they are more likely to continue with the treatment and to recommend the clinic to others.

Reason 4: Easy to Store and Compare

Digital scans can be stored permanently without losing quality. Unlike plaster models, they do not break or fade. This means doctors have a full record of the patient's foot shape and can go back to it anytime in the future.

Having these scans makes it easy to compare results over time. Doctors can check if the treatment is working, if the foot is changing, or if new problems are starting to appear. They can even place scans side by side or on top of each other to see the exact differences.

This kind of digital record helps doctors make better choices and take action earlier. With this, patients get better results and long-term care becomes more effective and less costly. When using the same 3D foot scanner over time, comparisons become consistent and highly reliable.

Reason 5: Saves Money and Builds Value

Using digital scans reduces waste and lowers the need for trial-and-error production. The exact data allows clinics and labs to plan materials more precisely and avoid remaking devices.

The faster workflow means clinics can see more patients in less time while keeping the same quality of service. This lowers costs, increases efficiency, and helps the clinic grow.

Patient satisfaction also has a financial benefit. Happy patients are more likely to return, to recommend the clinic to others, and to build its reputation. In the long run, this creates more growth and stability for the practice.

A foot scanner for insoles helps clinics create high-quality orthotics with fewer adjustments and better long-term results.

Conclusion

3D scanning is more than just a new tool. It changes the whole way orthopedic care is delivered. It brings better accuracy, faster processes, more comfort for patients, safer storage of data, and real cost savings. With a modern 3D foot scanner, clinics can fully digitize their workflow and produce more consistent insoles.

For clinics, the technology pays for itself through better outcomes, smoother workflows, and more satisfied patients. For patients, it means care that is quicker, more comfortable, and more reliable.

The future of orthopedic measurement is digital, and it is already here.

Ready to revolutionize your practice?

Discover how 3D scanning solutions and foot scanners for insoles can transform your workflow and improve patient outcomes. Book a demo today!

Co-Founder of LutraCAD, I'm a passionate software developer with a keen interest in 3D printing. Merging technology with creativity, I'm dedicated to pushing the boundaries of design and innovation.

Tags: 3D Scanning, Orthopedic Measurements, Digital Workflow, Patient Care,