Mill and 3D-print with one software package

With our software you can make different types of insoles with different production methods and materials for your orthotic supply. You can work with EVA, polyprop, positives, sandals for milling and 3D printing with FDM TPU and PP, SLS and MJF PA11, PA12 and more.

Full foot

Create full length soft or rigid insoles.

Rigid shells

Create 3/4 length rigid and soft shells.

Positives

For forming EVA, PP and Carbon Fibre.

Sandals

Convert your design to a sandal model.

Feature highlight

With the right tools at hand you can make fast and accurate changes to your designs. For example use our trim line editor to drag the line from any origin and change the shape.

With the software, you can choose prefab orthotics, Total Contact Inlay (TCI) or Total Contact Orthoses (TCO), and Sensorimotor orthotics.

Introducing our extensive library of templates and elements, they can easily be modified and customized to meet your specific needs. With our intuitive editing tools, you can modify and adapt these models to your unique requirements, ensuring that your designs are both accurate and efficient.

Our advanced workflow allows you to easily design custom insoles for your customers with just one streamlined process. With a range of production options available, you can choose the most efficient and cost-effective method for your needs at any given time. Whether you prefer 3D printing, milling, or traditional molding techniques, our workflow makes it easy to switch between methods and produce high-quality insoles with ease. Take your business to the next level with our innovative solution for custom insole design.

Our software allows you to define multiple density zones within your designs, giving you complete control over the structure and support of your models.

Our system allows for seamless import of 2D and 3D scans, imprints, and pressure plate data. Work with the data types that are most convenient for you, ensuring that your custom products are always designed with maximum accuracy and precision.

Our software automates the workflow for designing custom insoles with macros, streamlining the design process and making it faster and more efficient. With our powerful automation tools, you can create custom macros that automate repetitive tasks and speed up the design process, saving you time and effort. This allows you to focus on creating high-quality designs that meet your customers unique needs, without getting bogged down in tedious manual tasks.

Do you want to

know more about our software?

What Clients Say

We place huge value on strong relationships and have seen the benefit they bring to our business. Customer feedback is vital in helping us to get it right.

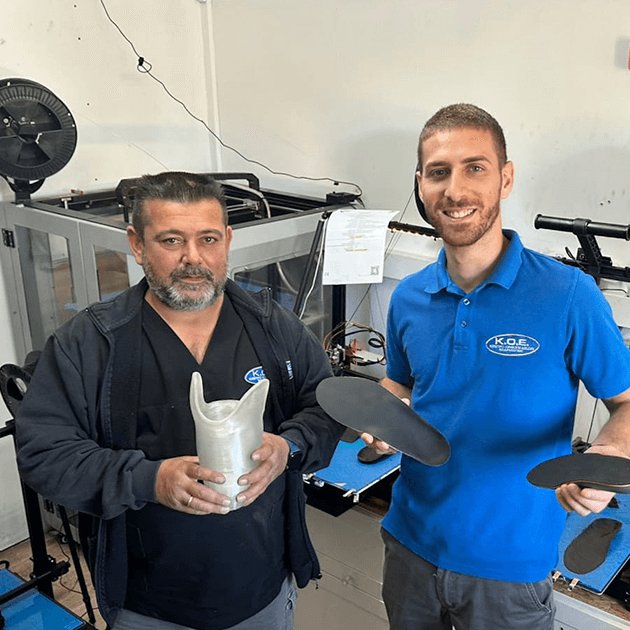

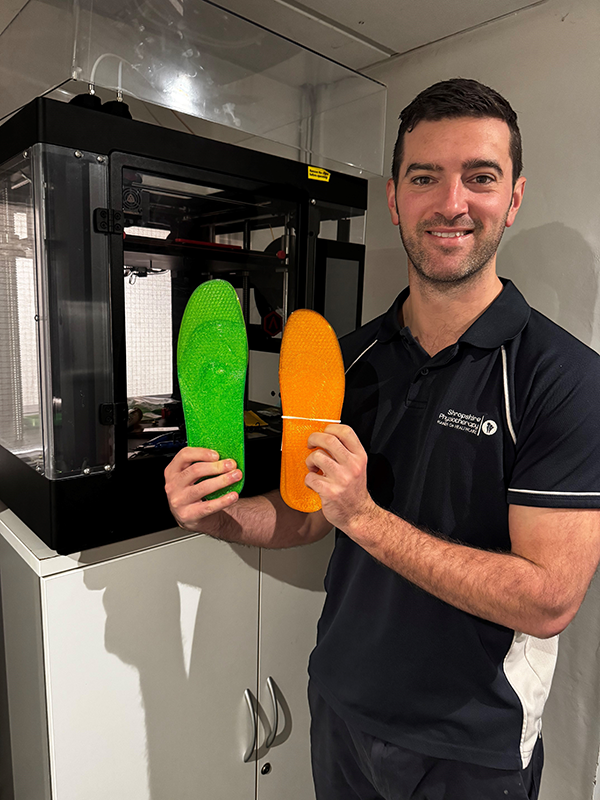

Thanks to the seamless integration between LutraCAD and our milling machines and printers, the transition has been incredibly smooth, and our production process has significantly accelerated. Moreover, customization is now truly tailored, thanks to the precision of the program.

Overall, I'm very satisfied with LutraCAD. The constant updates and new features demonstrate that LutraCAD is committed to improving their product, which helps us stay at the cutting edge of insole design.

We couldn't be happier with the support we've had from Jordy and Niels. LutraCAD is a great product that has transformed how we work. The software is quick, simple, and delivers fantastic results — saving us time while improving the quality of our orthotics.