Podotherapie van de Ven is a modern foot care practice committed to delivering high-quality orthotic solutions. Their team focuses on combining clinical expertise with efficient production methods, offering patients custom-made insoles designed to improve comfort, stability, and overall mobility.

Like many practices, they were searching for a way to streamline their workflow and remove inefficiencies from the traditional measurement and production process.

Podotherapie van de Ven Practice

Podotherapie van de Ven Practice

The Challenge before LutraCAD

Before adopting a digital workflow, the clinic relied on a mix of manual assessments, fragmented software tools, and outsourced production. While effective, the workflow was time-consuming and left little room for optimization:

- Foot measurements and assessments took longer than necessary

- Outsourcing extended delivery timelines

- Adjustments required significant back-and-forth

- Production capacity was limited

The team recognized the need for a solution that could unify scanning, design, and production into one streamlined system - without compromising accuracy.

The Transformation

The shift began when the practice introduced LutraCAD Insole Design Software, and a modern 3D printing setup. What once required multiple disconnected steps now happens in a single digital workflow.

In the video we recorded onsite, the transformation is clear:

Digital workflow demonstration1. Fast & accurate scanning

Using a 3D foot scanner, the practitioner captures the patient's foot shape with precision in seconds. The scan is immediately transferred to LutraCAD software, giving the practitioner full control over the file - no exporting, renaming, or manual syncing needed.

2. Intuitive digital design

Inside LutraCAD Insole Software, corrections, adjustments, and support elements are added with complete accuracy. What used to require manual craftsmanship is now reproducible and fully traceable.

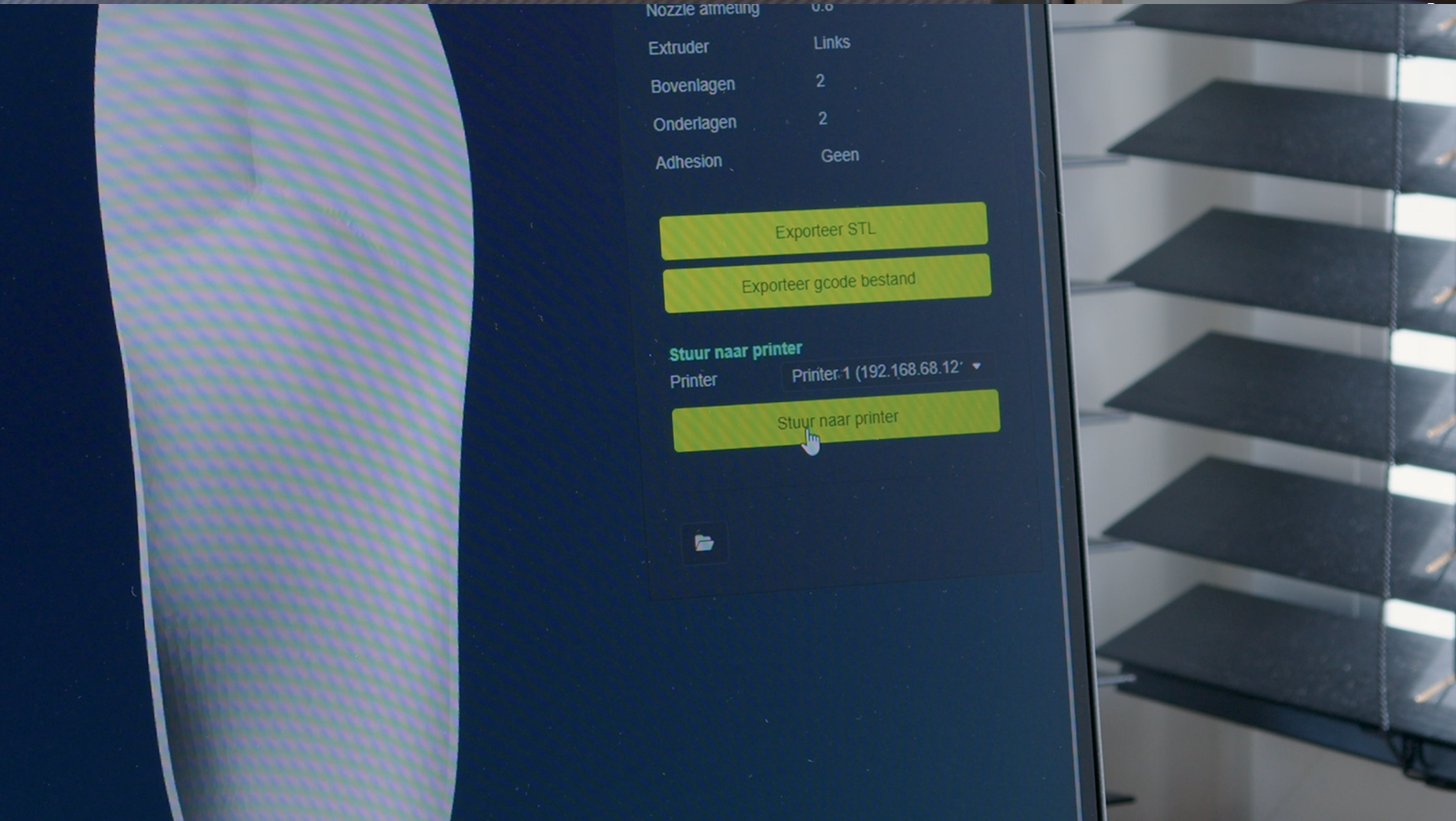

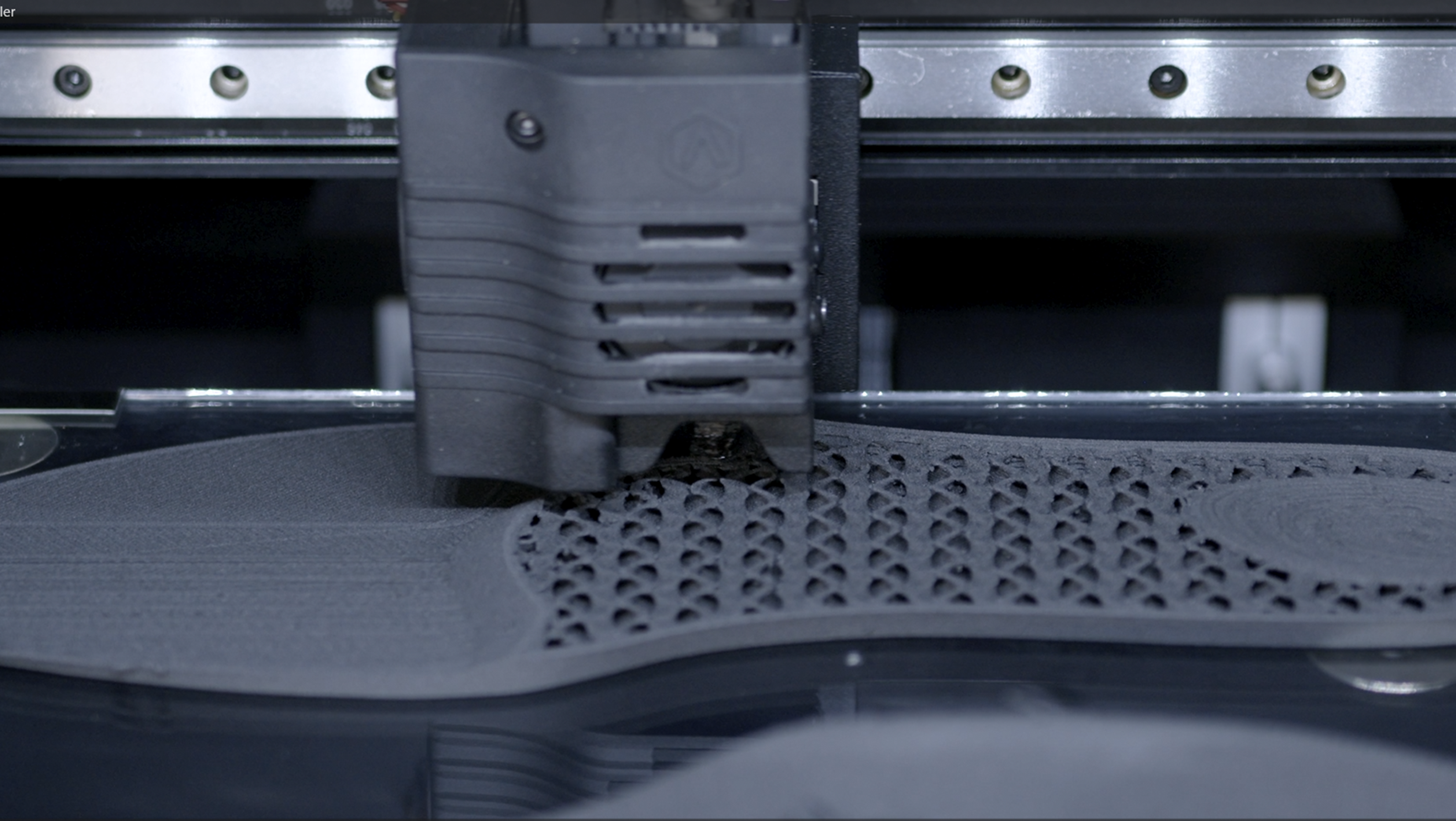

3. Production inside the clinic

The designed insole is sent directly to their in-house 3D printer.

The result: a functional, customized insole produced within hours instead of days.

This integrated setup gives the team an efficient digital chain from measurement to final product - all managed under one system.

Results and Benefits

Since implementing LutraCAD, the clinic has experienced a clear improvement across its workflow:

Shorter turnaround times

Patients receive their insoles faster thanks to an in-house 3D production line.

Higher precision

Digitally applied corrections ensure consistent quality and reproducibility for every pair.

Greater workflow control

From scan to design to print, everything runs through one connected platform.

Scalability without extra staff

What used to require lengthy manual steps can now be completed with fewer touchpoints, allowing the same team to help more patients.

Modern, professional patient experience

The digital workflow gives patients a clear, transparent view of their treatment - something many appreciate.

3D foot scanning process

3D foot scanning process

Why they chose LutraCAD

The practice chose LutraCAD for its:

- Ease of use

- Fast learning curve

- Strong support team

- Compatibility with multiple scanners and printers

- Full workflow integration

LutraCAD's team worked closely with the clinic to ensure a smooth onboarding. Within a short time, the practitioners were comfortable working independently in the software.

Conclusion

This case demonstrates how even smaller clinics can modernize their workflow with the right digital tools. By adopting LutraCAD, the practice successfully transitioned from a partially manual process to a fully digital production workflow - without losing the clinical expertise that defines their work.

They now operate with higher precision, shorter lead times, and a more scalable system that supports future growth.

More info?

At LutraCAD, we specialize in digital workflows for insole design, shoe lasts, midsoles, scanning, 3D printing, and milling. If you are considering upgrading your clinic or production facility, feel free to reach out - we're happy to help you choose the right setup.